Tamper-evident packaging has been around for a long time but is now more of an expectation, not an exception; specifically, in retail food packaging. Looking more closely at Ice Cream & Frozen Dessert brands, tamper evidence is becoming more and more prevalent.

This is being driven by the retailers and ultimately the consumers as they look for the best possible products. A package that offers some form of tamper evidence is going to provide some additional reassurance.

Not only does this added feature serve the consumer in terms of feeling confident in the integrity of a product, it also assists retailers to ensure that they are filling their shelves with untouched and safe products. While there are many different forms of tamper evident packaging, the goal of safety and security is consistent across the board.

Background

The term “tamper-evident” refers to a device or process that makes unauthorized access to a protected object easily detected. The idea is that some kind of action has to be taken to the package, whether it be to pull a tear band or break off a plastic tab, in order to be able to open or access the contents with ease. The tearing or breaking off of a piece of the container would then serve as the indication to the consumer and/or retailer that this product may have been tampered with and may not be safe for consumption.

Functionality

As defined earlier, “tamper-evident” doesn’t necessarily just refer to one process – as long as it protects the product from unauthorized access then it can be considered to be tamper evident. The most common types of tamper evidence within the retail frozen desserts and ice cream segments are: a heat seal or membrane, a secondary shrink band, or functional packaging.

Heat Seal

Commonly referred to as a freshness seal, the membrane is applied directly to the cup as part of the filling process. It typically requires special equipment but the membrane can be printed and offers brands another chance to convey their message. The consumer would remove the overcap and heat seal prior to consuming.

Shrink Band

Like the seal, the shrink band is a separate component but applied after filling in a secondary operation on a specialized piece of equipment. The clear plastic band can also be printed and would be removed by the consumer in order to access the contents.

Functional Packaging

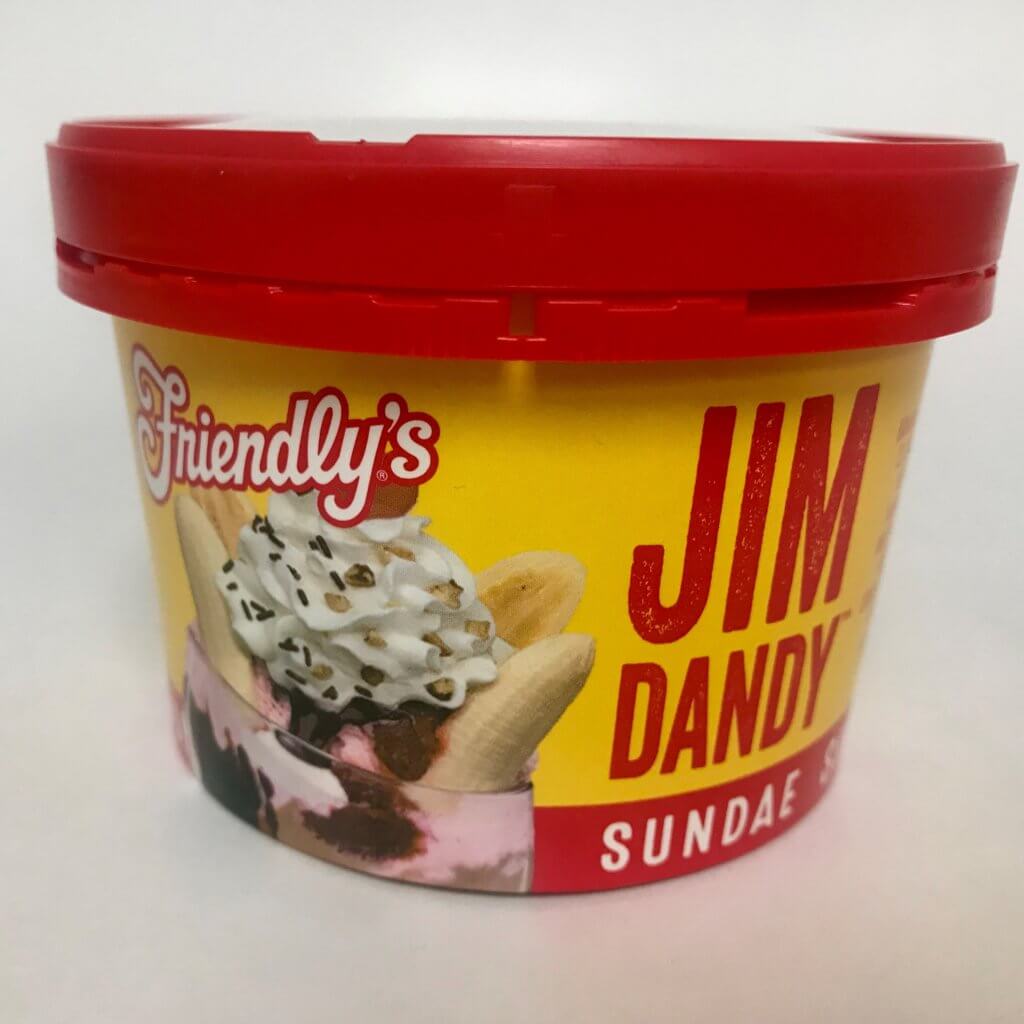

Unlike the seal and the band, functional packaging incorporates a tamper evident feature into the cup or lid by way of a tab to break or band to remove. In either case, there is a permanent change to the packaging which would indicate tampering. The packaging tends to be more complex but removes a secondary step from the filling process.

What this Means to You

There are a number of proven options available for ice cream and frozen dessert packaging to incorporate some form of tamper evidence. Each situation is different so brands should consider all options and make a decision based on what works best for their product, process, and Consumer.

About Double H:

Double H Plastics is a manufacturer of Plastic & Paperboard Packaging that services industries such as Ice Cream & Dairy, Consumer Products, Cereals, Convenience Foods and Pet Care. Through a unique injection molding process we use paperboard inserts and a variety of plastic resins to mold custom packaging solutions, including functional tamper evident lids. This process allows for exceptional graphics and superior functionality in a wide array of shapes and sizes.

In addition, Double H can supply Formed Paperboard Cups and Containers as well as Solid Injection Molded components and IML Packages. Sizes range from 3.6 Ounces to 5 Quarts.