Background

Double H specializes in composite lids; combining an injection molded rim with a printed paperboard insert for the purpose of bringing together exceptional graphics with the function and fit of plastic.

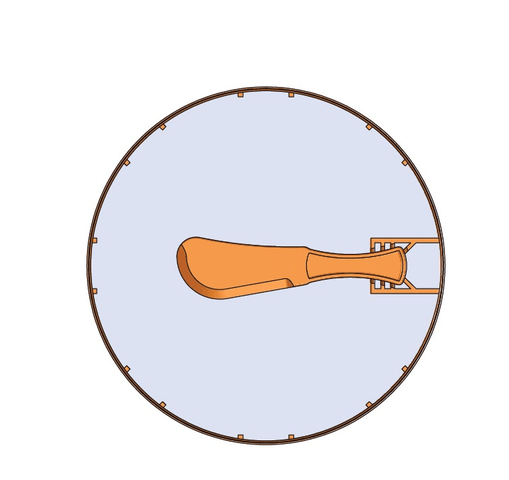

One of the benefits of this technology is the ability to create packaging with additional functionality; like a utensil, on the underside of the lid. The most popular utensil is a “Spoon Lid” for Ice Cream & Frozen Dessert. It’s currently offered in two main sizes, to fit 3.6 ounce and 8 ounce cups, and has been in the market for over 10 years.

Convenience

Consumers are making more and more food and snacking choices based on convenience, and new and innovative packaging can continue to add value. With the utensil integrated into the lid, there is no need for a secondary spoon; which is especially helpful away from home.

Whether it’s portion control or a way to reduce costs, some packages have been downsized so these single serve items don’t need a lid for reclosure. The lid is now utilized as a way to deliver the spoon.

Consumer Experience

While the addition of the spoon as part of the package provides convenience, it is important to note that the food grade plastic should not affect the taste profile of the ice cream. Nothing compares to a real spoon, but for consuming on the go, the plastic spoon is preferred to a wooden spoon option.

Typically, a heat seal membrane is applied once the cup is filled and before the lid is applied. This keeps the spoon clean during distribution and also serves as a form of tamper evidence. From a manufacturing perspective, the lid and heat seal can be applied inline.

The spoon is easily removed from the underside of the lid, rigid enough to use with frozen desserts, and made from a recyclable food grade plastic.

Other Applications

The spoon lid has grown in Ice Cream and Frozen Dessert, but the same concept can be applied in other markets. Similar spoons can be used with edible cookie dough and other savory snacks. Additional designs include a spork for prepared meals as well as a utensil for spreads.

Adding a functionality within the primary packaging allows the consumer to enjoy more products in different ways; in this case, on the move. Whatever the usage occasion, adding a utensil can add immense value to the packaging and the brand.

About Double H:

Double H Plastics is a manufacturer of Plastic & Paperboard Packaging that services industries such as Ice Cream & Dairy, Consumer Products, Cereals, Convenience Foods and Pet Care. Through a unique injection molding process we use paperboard inserts and a variety of plastic resins to mold custom packaging solutions, including functional tamper evident lids. This process allows for exceptional graphics and superior functionality in a wide array of shapes and sizes.

In addition, Double H can supply Formed Paperboard Cups and Containers as well as Solid Injection Molded components and IML Packages. Sizes range from 3.6 Ounces to 5 Quarts.